When it comes to ensuring the safe and efficient operation of your clothes dryer, proper venting is essential. Follow these guidelines to ensure your dryer is vented correctly and avoid potential issues:

Scope:

- Vent clothes dryers directly to the outdoors, except for ventless dryers equipped with a condensate drain.

- Use smooth metal ducting ≤ 35 feet in calculated length, supported ≤ every 12 feet.

- Locate duct terminus ≥ 3 feet from other openings.

- At the terminating end of the exhaust duct (at the exterior wall), install a louvered backdraft damper with a hood.

- Don’t cover the end of the duct with screening.

- Install per manufacturer’s instructions and local code.

- Do not use devices that remove lint and bring the heat back into the home. This adds unwanted moisture to the house.

- Do not exhaust dryers within 10 feet of the AC condenser, which could contribute to poor HVAC operations.

Description:

- Clothes dryers vent about a gallon of water for each typical load of laundry. Ensure proper venting to prevent moisture-related damage.

- Vent directly to the outside using approved exhaust duct. Avoid vinyl, nylon, and foil ducts.

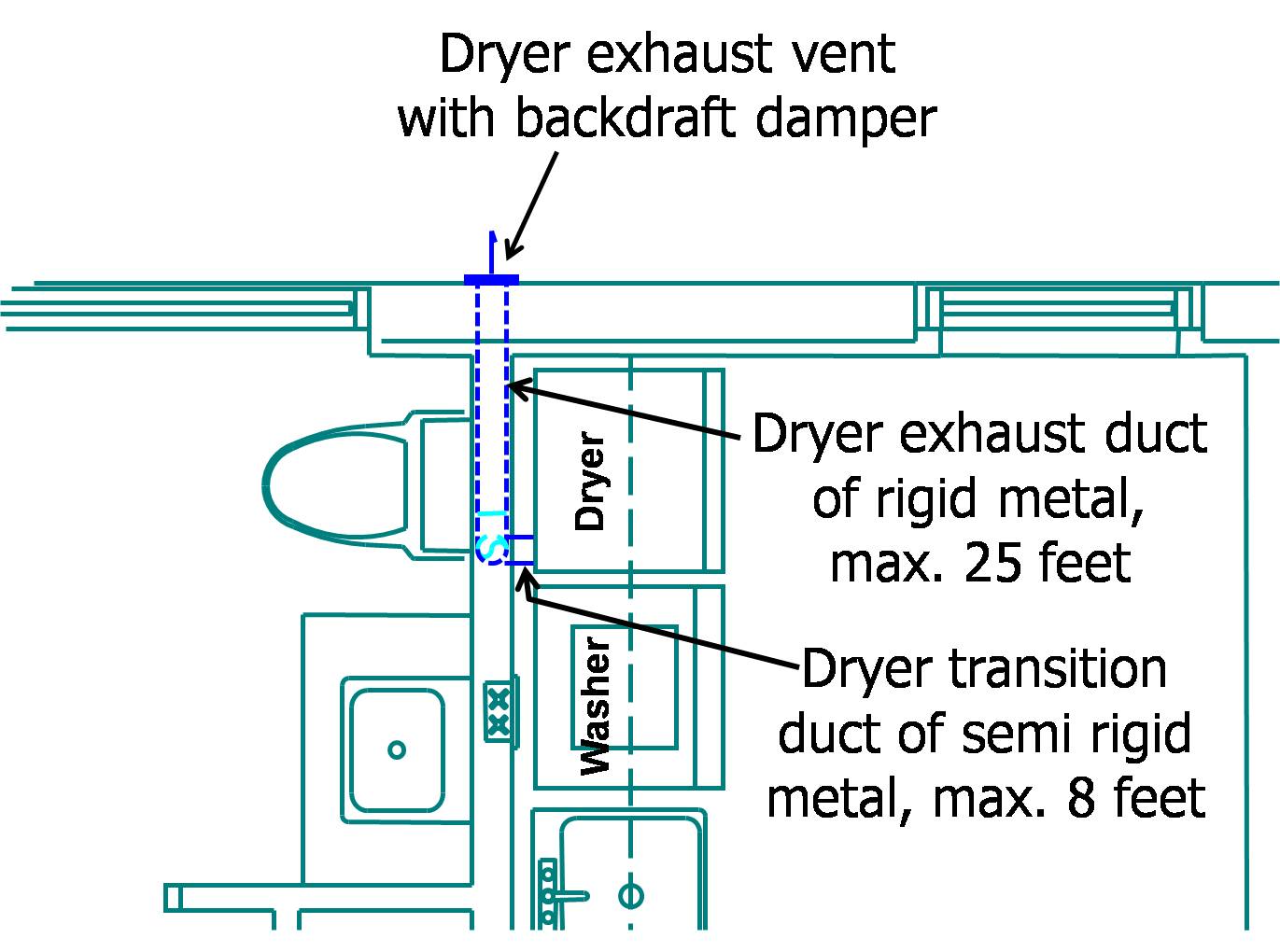

- Use rigid or semi-rigid metal ducts, 4 inches in diameter, with a smooth interior finish.

- Support the duct every 12 feet and avoid sags.

- The transition duct (connecting dryer to wall) can be up to 8 feet and should be UL-listed.

- Locate the exhaust terminal ≥ 3 feet from doors or windows and ≥ 10 feet from AC condensers.

- Install a louvered backdraft damper at the exterior wall.

- Do not use screens in the duct terminus.

- Insulate ducts in unconditioned spaces.

- Educate homeowners on regular maintenance, including cleaning lint filters and scheduling professional cleanings.

How to Install Dryer Exhaust Duct:

- Use rigid metal duct, 4 inches in diameter, supported every 12 feet.

- Connect the exhaust duct to a transition duct at the interior wall.

- Avoid terminating the duct at the roof.

- Install a backdraft damper at the exterior wall.

- Insulate ducts in unconditioned spaces.

Recommendations for Homeowners:

- Use a lint filter or screen.

- Clean the lint filter before/after each load.

- Have a professional technician clean the dryer exhaust duct annually.

- Service gas dryers regularly.

- Follow manufacturer’s instructions.

- Install a fire extinguisher, smoke alarm, and CO alarm in the laundry area.

Retrofit for Improved Dryer Venting

1. Inspect for Lint Buildup

Begin your retrofit journey by inspecting your dryer exhaust duct for lint buildup. Lint can accumulate over time, obstructing airflow and reducing your dryer’s efficiency.

2. Clean the Exhaust Duct

Once you’ve identified lint buildup, it’s time to clean the exhaust duct thoroughly. There are cleaning kits available for this purpose, ensuring you remove all obstructions.

3. Upgrade to Smooth Metal Duct

Consider replacing your existing ducting with smooth metal ducts, preferably at least 4 inches in diameter. Smooth metal ducts provide optimal performance and reduce the risk of lint accumulation.

4. Address Excessive Length and Angles

If your exhaust duct is excessively long or has multiple bends, it’s essential to address these issues. Lengthy or angled ducts can impede airflow. Consider rerouting the duct to a shorter, straighter, or more horizontal position. For challenging duct routes, an in-line booster fan can be a game-changer, improving overall airflow.

5. Consult Standard Work Specifications

For more in-depth guidance on safe clothes dryer venting, consult the U.S. Department of Energy’s Standard Work Specifications. These standards provide comprehensive insights into best practices for dryer venting.

Why Retrofit Matters:

A poorly performing exhaust duct can lead to several issues, including:

- Clothes remaining damp after drying cycles.

- Prolonged drying times, wasting energy and time.

- Overheating and a potential fire hazard due to lint buildup.

By retrofitting your dryer exhaust duct, you not only enhance your dryer’s performance but also ensure safety and energy efficiency.

Regular Inspections Are Key:

Remember that regular inspections and cleaning of the exhaust duct are essential for ongoing safe operation. Look out for crushed, kinked, or clogged ducts during inspections, and take action as needed.

Final Checks:

Inspect the exterior wall terminus of your duct. Ensure it has a hooded, louvered gravity damper for proper ventilation. If a screen covers the opening, replace it with a louvered damper for better airflow.

Compliance with Codes and Standards

ENERGY STAR Single-Family New Homes, Version 3/3.1 (Rev. 11)

Clothes dryer are not specifically addressed.

DOE Zero Energy Ready Home (Revision 07)

Exhibit 1 Mandatory Requirements.

Exhibit 1, Item 6) Certified under EPA Indoor airPLUS.

EPA Indoor airPLUS (Revision 04)

3.2 Rodent/Bird Screens for Building Openings. Provide corrosion-proof rodent/bird screens (e.g., copper or stainless steel mesh) for all building openings that cannot be fully sealed and caulked (e.g., ventilation system intake/exhaust outlets and attic vent openings). Exception: This requirement does not apply to clothes dryer vents.

4.6 Local Exhaust for Known Pollutant Sources. Conventional clothes dryers shall be vented to the outdoors. Electric condensing dryers shall be plumbed to a drain according to manufacturer’s instructions.

2009, 2012, 2015, 2018, and 2021 International Residential Code (IRC)

M1502 Clothes Dryer Exhaust. Follow manufacturer’s instruction and the requirements of Section M1502 which states that dryer exhaust systems to be independent of all other systems and convey the moisture to the outdoors, unless listed and labeled condensing (ductless) dryers are used. M1502 also specifies dryer duct materials (metal with smooth interior, not plastic), dimensions (min. 4 inch diameter), support (min. every 4 feet in 2009 IRC, every 12 ft in 2012-2021 IRC), calculated duct length (max 25 feet in 2009 IRC, 35 feet in 2012-2021 IRC), transitions (max. 8 feet), exhaust duct terminations (to outside of building at least 3 feet from building opening, with damper, no screens), etc. See M1502 for more requirements.

Retrofit: 2009, 2012, 2015, 2018, and 2021 IRC

Section R102.7.1 Additions, alterations, or repairs. Additions, alterations, renovations, or repairs shall conform to the provisions of this code, without requiring the unaltered portions of the existing building to comply with the requirements of this code, unless otherwise stated. (See code for additional requirements and exceptions.)

Appendix J regulates the repair, renovation, alteration, and reconstruction of existing buildings and is intended to encourage their continued safe use.

Ensure your clothes dryer operates safely and efficiently by following these guidelines for proper venting. For more details and compliance information, refer to relevant building codes and standards.

For immediate service or consultation, you may contact us at Allied Emergency Services, INC.

Contact Information:

- Phone: 1-800-792-0212

- Email: Info@AlliedEmergencyServices.com

- Location: Serving Illinois, Wisconsin, and Indiana with a focus on the greater Chicago area.

If you require immediate assistance or have specific questions, our human support is readily available to help you.

Disclaimer: This article is intended for informational purposes only. For professional advice, consult experts in the field.