Ensuring Durability and Compliance in Hurricane Zones: Drip Edge Installation Over Underlayment

Hurricanes pose significant risks to residential and commercial properties, especially to roofing systems. An essential component of roofing that plays a crucial role in both water deflection and wind resistance is the drip edge. Installing drip edges correctly over underlayment according to the F-DE-1 specification is critical for enhancing the roof’s durability and compliance with building codes.

Importance of Drip Edges in Hurricane Prone Areas

Drip edges are not just functional; they are crucial for protecting the edges of the roof from water ingress and wind uplift. In hurricane-prone areas, the proper installation of a drip edge over underlayment becomes even more vital due to the increased risk of high winds and driving rain. The drip edge helps direct water away from the fascia and into the gutter, reducing the risk of water damage and wood rot at the roof edges.

Understanding F-DE-1 Specifications for Drip Edge Installation

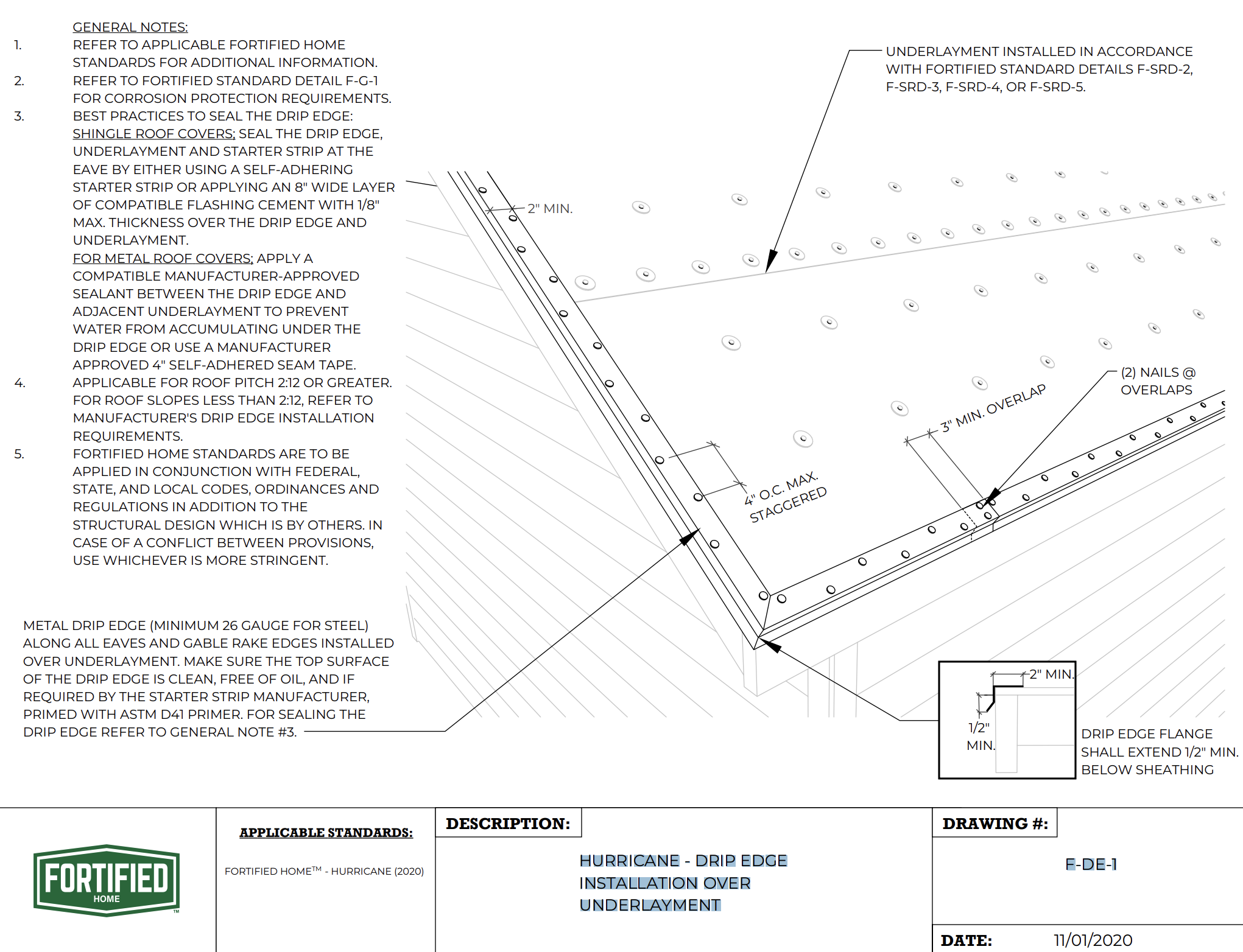

The F-DE-1 specification delineates precise guidelines for installing drip edges over underlayment, an essential practice for achieving the best protection against severe weather conditions. Following these guidelines helps maintain the integrity of your roof during hurricanes by preventing water ingress and ensuring the durability of the roofing materials.

Key Details from F-DE-1 Specification:

- Material Specifications: Use a metal drip edge of at least 26 gauge if it’s steel, ensuring it covers all eaves and gable rake edges over the underlayment.

- Installation Process: The drip edge should extend a minimum of 2 inches over the overlaps, with at least two nails securing each section. This setup guarantees a firm attachment that resists high winds. Staggered fasteners 4 inches on center maximum.

- Underlayment Compliance: The underlayment installation must comply with FORTIFIED standard details F-SRD-2, F-SRD-3, F-SRD-4, or F-SRD-5, as these are designed to provide additional resistance against the elements.

- Sealing Practices: For shingle roofs, sealing at the eaves involves either using a self-adhering starter strip or applying a compatible flashing cement layer to secure the drip edge, underlayment, and starter strip together. For metal roofs, use a manufacturer-approved sealant or a 4-inch self-adhered seam tape between the drip edge and underlayment.

Importance of Compliance with Building Codes and Standards

While adhering to the F-DE-1 specifications, it is also crucial to align with the FORTIFIED Home™ standards and local building regulations. In cases where the FORTIFIED standards and local codes diverge, the more stringent requirements should always be applied. This ensures your roofing system not only meets but exceeds the necessary criteria for durability and safety in hurricane-prone environments.

Conclusion: The Role of Professional Installation

To ensure that your roof meets all the required standards for hurricane resistance, it is recommended to hire certified roofing professionals who are familiar with local building codes and the specific challenges presented by hurricane-prone environments. Professional installation guarantees that your roofing system, including the drip edge, is installed correctly, providing maximum protection against the elements.

For immediate service or consultation, you may contact us at Allied Emergency Services, INC.

Contact Information:

Phone: 1-800-792-0212

Email: Info@AlliedEmergencyServices.com

Location: Serving Illinois, Wisconsin, and Indiana with a focus on the greater Chicago area. If you require immediate assistance or have specific questions, our human support is readily available to help you.

Disclaimer: This article is intended for informational purposes only. For professional advice, consult experts in the field.