Properly selecting and installing fasteners for deck connectors is critical to ensuring the structural integrity and safety of your deck. Simpson Strong-Tie offers a variety of fasteners specifically designed and tested for use with their connectors, ensuring reliable performance and compliance with building codes. This blog will cover the importance of using the correct fasteners for deck connectors, the types of fasteners available, and best practices for installation.

Importance of Using Correct Fasteners for Deck Connectors

Structural Integrity

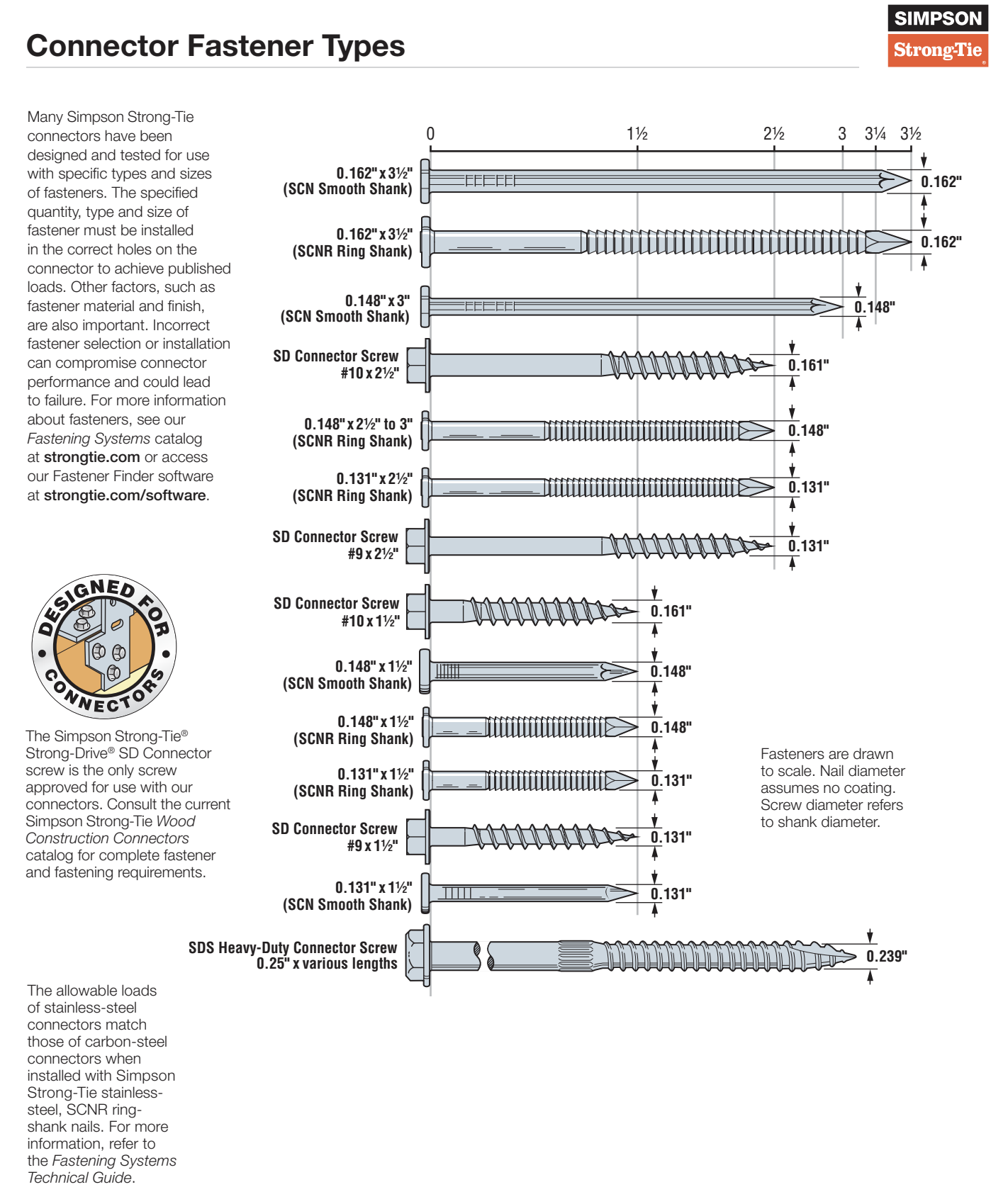

Using the specified quantity, type, and size of fasteners in the correct holes on the connector is essential to achieving the published load capacities. Incorrect fastener selection or installation can compromise the performance of the connector, potentially leading to structural failures.

Compatibility and Performance

Simpson Strong-Tie connectors are designed and tested with specific fasteners to ensure optimal performance. The material and finish of the fasteners are also important factors that affect durability and resistance to corrosion.

Types of Simpson Strong-Tie Fasteners for Deck Connectors

Strong-Drive® SD Connector Screw

The Strong-Drive® SD Connector Screw is the only screw approved for use with Simpson Strong-Tie connectors. It is designed to provide superior holding power and is easy to install without predrilling.

- Features:

- Tested and approved for use with Simpson Strong-Tie connectors.

- Provides high shear strength and holding power.

- Available in various sizes to match specific connector requirements.

SCNR Ring-Shank Nails

For stainless-steel connectors, Simpson Strong-Tie SCNR Ring-Shank Nails are the recommended fasteners. These nails ensure that the allowable loads of stainless-steel connectors match those of carbon-steel connectors.

- Features:

- Made from stainless steel for superior corrosion resistance.

- Ring-shank design provides excellent holding power.

- Available in various sizes to match specific connector requirements.

Additional Fastener Types

Simpson Strong-Tie offers a range of other fasteners designed for specific applications and environments. These include:

- Stainless-Steel Fasteners: Ideal for environments with high corrosion potential, such as coastal areas.

- Galvanized Fasteners: Provide good corrosion resistance for most exterior applications.

- Heavy-Duty Screws: Designed for high-load applications and engineered wood products.

Best Practices for Installing Deck Connector Fasteners

Follow Manufacturer Specifications

Always refer to the Simpson Strong-Tie Wood Construction Connectors catalog for complete fastener and fastening requirements. This ensures that you are using the correct fasteners and installation methods for each specific connector.

Use the Correct Quantity and Size

Ensure that you use the specified quantity and size of fasteners for each connector. Installing too few fasteners or using the wrong size can significantly reduce the load capacity of the connection.

Install Fasteners in the Correct Holes

Place fasteners in the designated holes on the connector to achieve the published load capacities. Misplacing fasteners can compromise the performance of the connection.

Consider Material and Finish

Select fasteners with the appropriate material and finish for the application environment. For example, use stainless-steel fasteners in coastal areas to prevent corrosion.

Consult Fastener Finder Software

For more information about fasteners, you can access the Fastener Finder software at strongtie.com/software. This tool helps you identify the right fasteners for your specific connectors and applications.

Conclusion

Using the correct fasteners for deck connectors is essential for ensuring the safety and durability of your deck. Simpson Strong-Tie offers a variety of fasteners specifically designed and tested for use with their connectors, providing reliable performance and compliance with building codes. Always follow manufacturer specifications and best practices for installation to achieve optimal results.

For immediate service or consultation, you may contact us at Allied Emergency Services, INC.

Contact Information:

- Phone: 1-800-792-0212

- Email: Info@AlliedEmergencyServices.com

- Location: Serving Illinois, Wisconsin, and Indiana with a focus on the greater Chicago area.

If you require immediate assistance or have specific questions, our human support is readily available to help you.

Disclaimer: This article is intended for informational purposes only. For professional advice, consult experts in the field.