When constructing a deck, choosing the right connectors and fasteners is crucial to ensure its longevity and structural integrity. Exposure to weather, treatment chemicals, and other environmental factors can significantly increase the risk of corrosion. This blog will discuss the importance of selecting appropriate coatings for deck connectors and fasteners, the options available, and best practices for corrosion resistance.

Corrosion Issues in Deck Construction

Environmental Factors

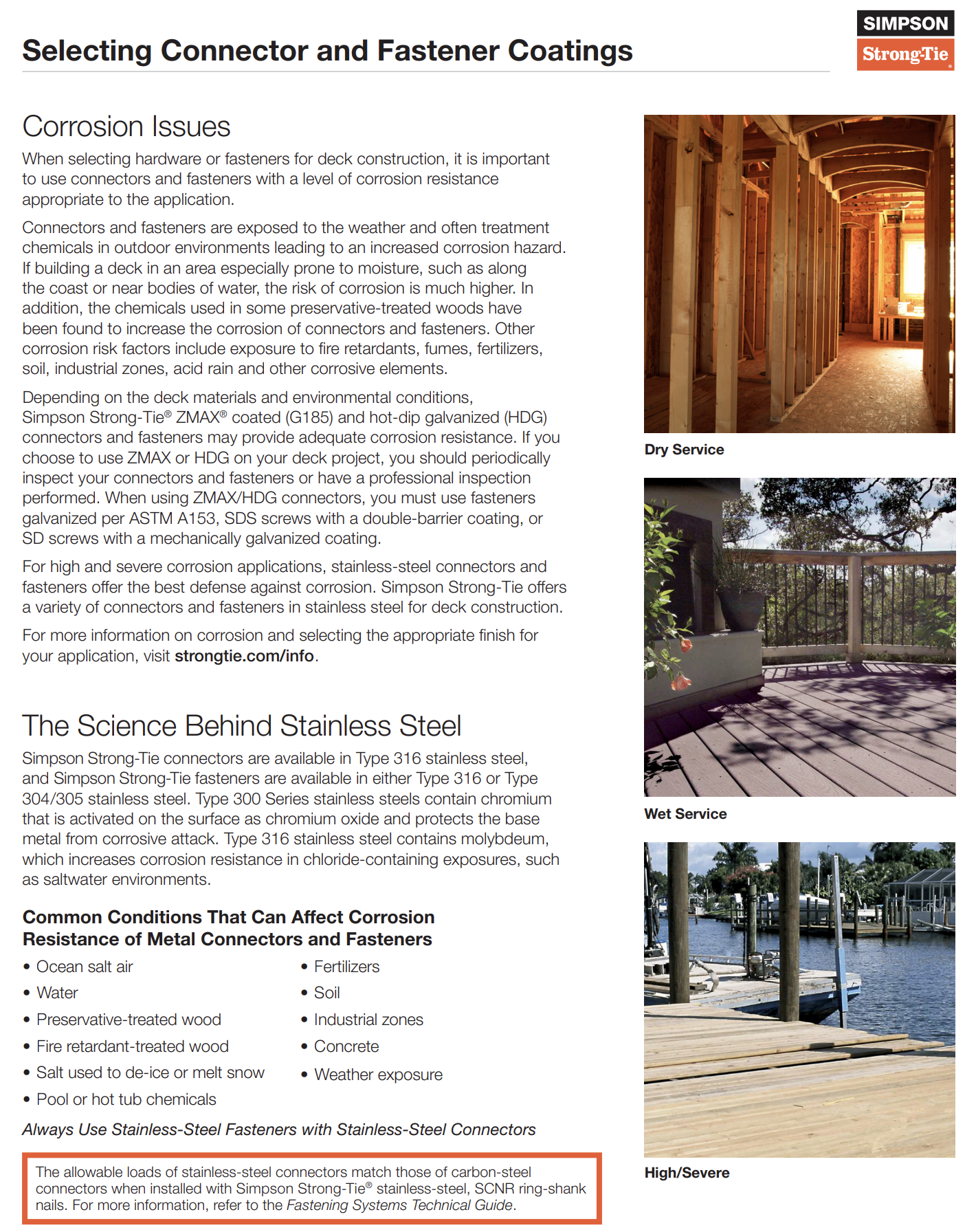

Deck connectors and fasteners are constantly exposed to various environmental conditions that can accelerate corrosion. These include:

- Moisture: Particularly prevalent in coastal areas or near bodies of water.

- Chemicals in Treated Wood: Certain preservatives can increase corrosion rates.

- Fire Retardants: Chemicals used for fire resistance can be corrosive.

- Industrial Zones: Exposure to industrial fumes and pollutants.

- Soil and Fertilizers: Contact with soil and fertilizers can introduce corrosive elements.

- Weather: Acid rain, snow, and salt used for de-icing can cause significant corrosion.

- Pools and Hot Tubs: Chemicals used in pools and hot tubs.

Consequences of Corrosion

Corrosion can weaken the structural integrity of the deck, leading to potential safety hazards. Regular inspection and maintenance are essential to ensure the longevity of the deck structure.

Simpson Strong-Tie® Solutions for Corrosion Resistance

ZMAX® Coated and Hot-Dip Galvanized (HDG) Connectors and Fasteners

For areas with moderate moisture and exposure, Simpson Strong-Tie offers ZMAX® coated (G185) and hot-dip galvanized (HDG) connectors and fasteners. These coatings provide a robust barrier against corrosion.

- ZMAX® Coating: A G185 coating providing enhanced corrosion resistance.

- Hot-Dip Galvanized (HDG): Conforms to ASTM A153 standards, offering a thicker layer of zinc for improved durability.

Best Practices

- Inspection: Periodically inspect connectors and fasteners for signs of corrosion.

- Matching Fasteners and Connectors: Use fasteners galvanized per ASTM A153, SDS screws with a double-barrier coating, or SD screws with a mechanically galvanized coating when using ZMAX/HDG connectors.

Stainless-Steel Connectors and Fasteners

For high and severe corrosion environments, stainless steel is the best choice. Simpson Strong-Tie offers a range of connectors and fasteners in Type 316 and Type 304/305 stainless steel.

The Science Behind Stainless Steel

- Type 300 Series Stainless Steel: Contains chromium, which forms a protective layer of chromium oxide on the surface to prevent corrosion.

- Type 316 Stainless Steel: Contains molybdenum, which enhances corrosion resistance in chloride-rich environments, such as saltwater.

Common Conditions Affecting Corrosion Resistance

- Ocean Salt Air: High salinity environments accelerate corrosion.

- Water Exposure: Continuous exposure to water increases corrosion risk.

- Treated Wood: Chemicals in preservative-treated and fire retardant-treated wood can be corrosive.

- De-Icing Salts: Salt used to melt snow can cause corrosion.

- Pool Chemicals: Chlorine and other chemicals used in pools and hot tubs.

- Fertilizers and Soil: Contact with soil and fertilizers introduces corrosive elements.

- Industrial Pollutants: Exposure to industrial fumes and chemicals.

- Concrete: Can affect the corrosion resistance of metal connectors and fasteners.

Best Practices for Using Connectors and Fasteners

Always Use Stainless-Steel Fasteners with Stainless-Steel Connectors

To prevent galvanic corrosion, it is crucial to use stainless-steel fasteners with stainless-steel connectors. This ensures compatibility and maximizes corrosion resistance.

Regular Maintenance and Inspection

Conduct regular inspections to identify any signs of corrosion early. This allows for timely maintenance and replacement of affected components, ensuring the deck remains safe and structurally sound.

Consult Manufacturer Guidelines

Refer to the Simpson Strong-Tie Fastening Systems catalog and use the Fastener Finder software at strongtie.com/software for specific recommendations on fasteners and connectors suitable for your application.

Conclusion

Selecting the appropriate coatings for deck connectors and fasteners is essential to protect your deck from corrosion and ensure its longevity. Simpson Strong-Tie offers a range of solutions, including ZMAX® coated, hot-dip galvanized, and stainless-steel fasteners, to meet various environmental challenges. By following best practices and conducting regular maintenance, you can build a durable and safe deck.

For immediate service or consultation, you may contact us at Allied Emergency Services, INC.

Contact Information:

- Phone: 1-800-792-0212

- Email: Info@AlliedEmergencyServices.com

- Location: Serving Illinois, Wisconsin, and Indiana with a focus on the greater Chicago area.

If you require immediate assistance or have specific questions, our human support is readily available to help you.

Disclaimer: This article is intended for informational purposes only. For professional advice, consult experts in the field.