Welcome to the world of nails, where the smallest details can make a significant impact on the success of your residential construction projects. At Allied Emergency Services, we understand that choosing the right nails is crucial for ensuring the longevity and structural integrity of your roofing, siding, windows, and more. In this blog post, we delve into the fascinating world of nails, exploring their various types, applications, and the psychology behind their selection. Get ready to elevate your carpentry skills and create masterful constructions that stand the test of time.

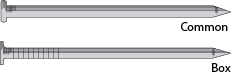

Common and Box Nails

- Sizes: 16 penny (d) common and box nails for general framing, 8d and 10d common and box nails for toenailing, and 6d and 8d common and box nails for subfloor, wall, and roof sheathing.

- Application: General framing & rough carpentry

Scaffold Nails

- Sizes: 8d and 10d are the most common sizes used for scaffolds, bracing, and temporary fastening.

- Application: Scaffolds, bracing and any temporary fastening that must later be removed.

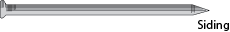

Siding Nails

- Sizes: The most common sizes include 4d, 6d, and 8d.

- Application: Exterior and interior trim, siding, and paneling installations, where large nailheads should not be visible.

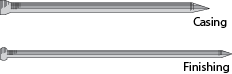

Casing and Finish Nails

- Sizes: The most common sizes include 4d, 6d, and 8d.

- Application: Exterior and interior trim, siding, and paneling installations, where large nailheads should not be visible.

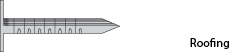

Roofing Nails

- Sizes: Size depends on thickness of roofing and deck material.

- Application: Roofing nails are specially designed for roofing materials, but often used for vinyl siding.

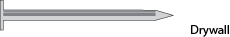

Drywall Nails

- Sizes: 4d to 6d, depending on the drywall thickness. 1/2-inch drywall use 4d drywall nails.

- Application: Drywall nails are specially designed for drywall materials.

Specialty Nails

- Hardwood Strip Flooring:

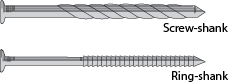

- 8d hardwood nails or 2-1/2-inch hardened, spiral-threaded (screw-shanked) nails are recommended for securing hardwood strip flooring. These nails provide excellent holding power, ensuring a secure and stable installation.

- Underlayment Grade Plywood (1/2-inch and thinner):

- 3d ring-shank nails are suitable for securing underlayment grade plywood over subflooring. The ring-shank design provides increased grip and helps prevent the nails from backing out over time.

- Sturd-I-Floor Panels (19/32 through 3/4-inch):

- 4d deformed-shank nails are commonly used to fasten Sturd-I-Floor panels. The deformed shank provides improved holding power, ensuring a sturdy and reliable installation.

- 1/4-inch Panels:

- For 1/4-inch panels, you can use either 3/4-inch or 1-inch brads, 3d finish nails, or 1-inch blue lath nails (if no objection to heads showing). These nails are suitable for securing lightweight panels and provide adequate holding strength for their thickness.

- Exterior Applications:

- For exterior applications, it is recommended to use galvanized or coated nonstaining nails or fasteners. These nails are resistant to corrosion and provide long-lasting performance, even when exposed to the elements.

Nailing Techniques and Spacing

- Nail Placement: Place nails accurately to maximize their holding power and minimize the risk of splitting the wood. Aim for the strongest areas, such as the center of the stud or joist, to ensure a secure attachment.

- Nail Spacing: For most applications, spacing nails about 6 inches apart is generally sufficient. However, closer spacing may be necessary for thin panels that have a higher tendency to buckle. Follow manufacturer recommendations and building codes for specific spacing requirements.

- Predrilling: In certain situations, predrilling pilot holes before inserting nails is necessary, especially when working close to panel edges. Use a drill bit slightly smaller in diameter than the nail to ensure a snug fit and reduce the chances of wood splitting.

- Panel Buckling Prevention: Proper nail spacing and placement can help prevent panel buckling, which occurs when the wood panels warp or bulge between nails. This is particularly important for large and thin panels. Consult industry guidelines or the manufacturer’s recommendations for specific panel dimensions and appropriate nail spacing.

By understanding the different types of nails and their applications in residential construction, you are equipped with the knowledge to enhance the quality and durability of your projects. Remember, even the smallest details, like nail selection and spacing, can have a significant impact. Allied Emergency Services is here to support you every step of the way, providing exceptional carpentry services and expert guidance. Start incorporating the power of nails into your construction projects and witness the transformative difference they can make.

By adopting these nailing techniques and spacing guidelines, you can enhance the structural integrity and overall quality of your residential construction projects.

Remember, each construction project may have unique requirements, so it’s essential to consult relevant building codes, manufacturer guidelines, and industry best practices to ensure the appropriate nailing techniques and spacing for specific applications.

At Allied Emergency Services, we specialize in providing exceptional roofing, siding, window installation, and emergency services. Our team of experts is well-versed in the art of nailing and can assist you in achieving outstanding results for your residential construction projects.

Contact us at 1-800-792-0212 or visit our website www.alliedemergencyservices.com to learn more about our services and how we can support your carpentry needs. Let’s create remarkable structures together, one nail at a time.

#Nails #Carpentry #Construction #BuildingMaterials #Woodworking #HomeImprovement #DIYProjects #Roofing #Siding #Flooring #Renovation #ToolsoftheTrade #ContractorLife #HomeConstruction #BuildingIndustry