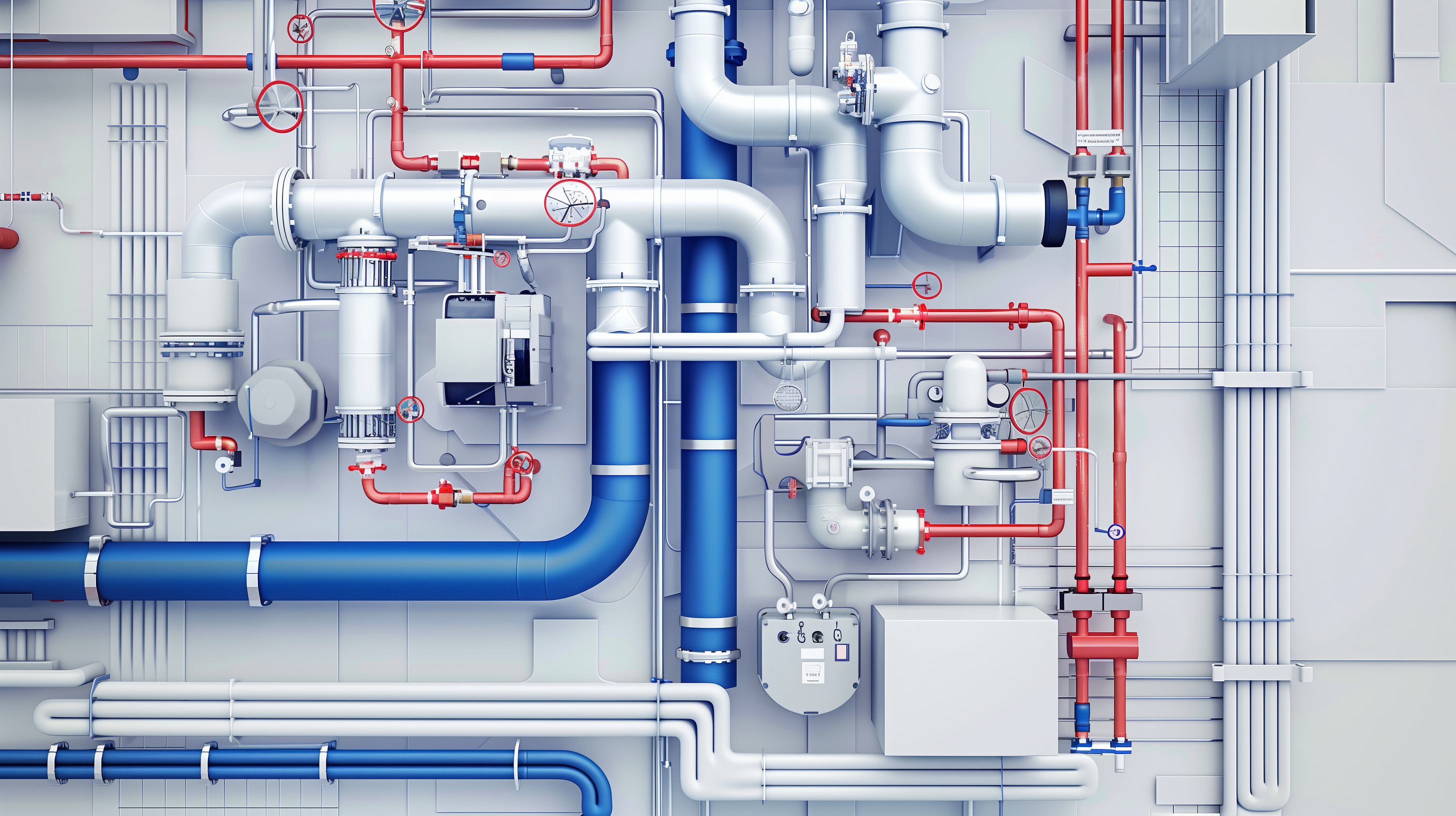

The Importance of Insulating Mechanical and Hot Water Piping

Proper insulation of mechanical system piping and service hot water systems is crucial for energy efficiency, reducing operating costs, and ensuring compliance with building codes. Piping insulation minimizes heat loss or gain during the transport of fluids, while proper system design and controls improve both energy and water conservation. Builders, contractors, and designers must adhere to the 2015 IECC/IRC requirements to ensure installations meet safety, efficiency, and performance standards.

Why Insulate Mechanical Piping and Service Hot Water Systems?

Benefits of Proper Piping Insulation

- Energy Savings

- Insulated piping prevents heat loss in hot water systems and reduces the energy needed to maintain desired temperatures.

- Lower Operating Costs

- Improved efficiency translates to lower utility bills for homeowners.

- Comfort Improvement

- Consistent water temperatures ensure a better user experience and reduce the time spent waiting for hot water.

- Enhanced System Longevity

- Proper insulation and protection from environmental factors, such as UV radiation and extreme weather, extend the life of piping systems.

Key Code Requirements for Piping Insulation

IECC/IRC Compliance Overview

The 2015 IECC/IRC mandates specific standards for mechanical system piping and service hot water systems:

- Mechanical Piping Insulation

- Per Section R403.4/N1103.4, piping carrying fluids above 105°F (41°C) or below 55°F (13°C) must be insulated to a minimum of R-3.

- Piping Protection

- R403.4.1/N1103.4.1 requires that insulation exposed to weather be shielded from damage caused by sunlight, moisture, and wind. Adhesive tape is not permitted as a protective covering.

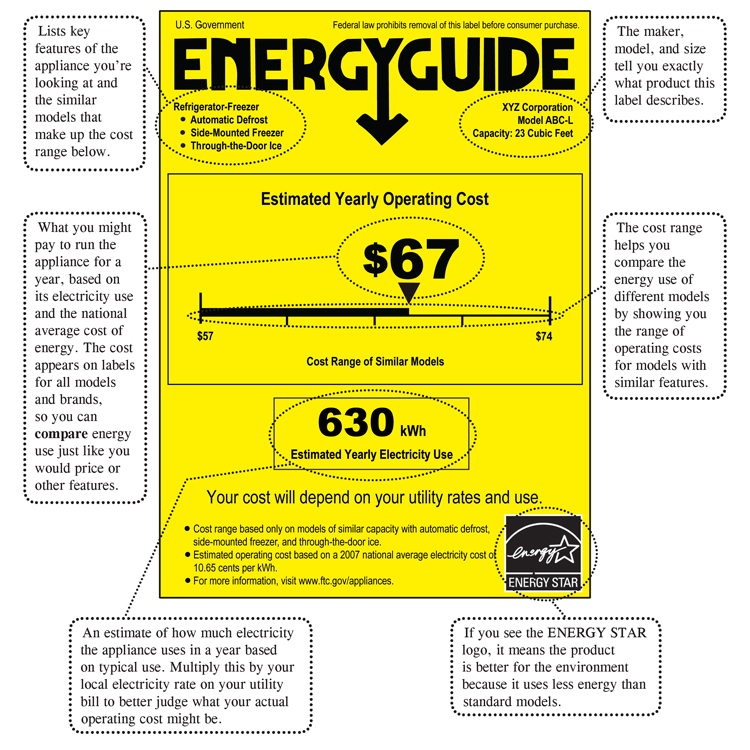

- Service Hot Water Systems

- R403.5/N1103.5 specifies energy-saving measures for service hot water systems, requiring proper circulation and temperature maintenance controls.

- Demand Recirculation Systems

- Per R403.5.2/N1103.5.2, demand recirculation systems must have controls to start the pump upon demand and limit the water temperature in cold water lines to 104°F (40°C).

Plan Review Checklist for Code Compliance

During the plan review phase, construction documents must include detailed information about piping insulation, design, and controls:

Required Documentation

- Insulation Materials and R-Values

- Specify the type of insulation used and confirm it meets the R-3 minimum requirement.

- Piping Design and Layout

- Include details on piping size, length of runs, and fluid temperatures for both mechanical and hot water systems.

- Protection Measures

- Indicate how exposed piping will be protected from weather and UV damage.

- Controls

- Provide information on circulation pumps, temperature sensors, and control systems for both hot water and mechanical systems.

Ensuring Compliance with Energy Efficiency Standards

- Compliance with mandatory provisions such as mechanical piping insulation and hot water system controls must be demonstrated, regardless of whether a prescriptive, performance, or Energy Rating Index (ERI) path is chosen.

- Builders aiming for high-efficiency certifications, such as the DOE Zero Energy Ready Home program, should adhere to additional water efficiency measures, including compact plumbing design and use of WaterSense-certified fixtures.

Best Practices for Insulating Mechanical Piping

- Select the Right Insulation Material

- Use materials with a thermal resistance of R-3 or higher, such as fiberglass, foam rubber, or polyethylene.

- Ensure Complete Coverage

- Insulate all exposed piping, including elbows and joints, to prevent thermal bridging.

- Protect Insulation from Weather

- Use protective coverings to shield outdoor piping from sunlight, moisture, and wind. Approved solutions include rigid PVC or aluminum jacketing.

- Use Heat Trace Systems for Cold Climates

- In cold regions, consider installing heat trace systems with automatic controls to maintain water temperatures and prevent freezing. Ensure compliance with IEEE 515.1 and UL 515 standards.

Field Inspection Guidelines

Inspection Checklist

Field inspections should be conducted during the rough-in and final stages to verify compliance with approved construction documents and code requirements. Inspectors should check the following:

- Insulation Installation

- Confirm that piping insulation meets the minimum R-3 requirement and is properly installed without gaps or voids.

- Protection Measures

- Ensure that outdoor piping insulation is shielded from UV radiation, moisture, and wind using approved materials.

- Piping and Run Lengths

- Verify that piping diameter and run lengths align with approved plans.

- Circulation and Temperature Controls

- Check that circulation pumps, temperature sensors, and automatic controls have been correctly installed and are operational.

- Demand Recirculation Systems

- Ensure that pumps are controlled by user-activated sensors and maintain water temperature within the specified limit.

Conclusion

Proper insulation and control of mechanical piping and service hot water systems are key components in creating energy-efficient and code-compliant buildings. By adhering to 2015 IECC/IRC standards, builders can enhance energy conservation, improve occupant comfort, and reduce long-term operating costs.

For expert guidance on meeting code requirements for mechanical system piping insulation and service hot water systems, contact Allied Emergency Services, INC. Our team specializes in ensuring compliance with the latest building codes and delivering high-performance solutions for residential and commercial projects.

Contact Information:

Phone: 1-800-792-0212

Email: Info@AlliedEmergencyServices.com

Location: Serving Illinois, Wisconsin, and Indiana, with a focus on the greater Chicago area.

Disclaimer: This article is intended for informational purposes only. For professional advice, consult experts in the field.