Ensuring Code Compliance for Heat Pump Water Heater (HPWH) Installations

Heat pump water heaters (HPWHs) are a highly efficient alternative to traditional electric-resistance water heaters. By utilizing a vapor-compression refrigerant cycle, HPWHs transfer heat from surrounding air to water, significantly reducing energy consumption. However, HPWHs require specific considerations for location, ventilation, condensate drainage, and electrical connections to ensure proper performance and compliance with applicable codes.

This blog provides essential information for code officials, builders, designers, and contractors regarding the plan review and field inspection process for HPWH installations based on the 2015 and 2018 International Residential Code (IRC) and International Energy Conservation Code (IECC). Adhering to these guidelines will ensure smoother plan reviews, uniform inspections, and greater compliance with energy and safety standards.

Key Code Requirements for Heat Pump Water Heaters

General Installation Requirements

Per IRC Chapter 28, HPWHs must be installed in accordance with:

- Manufacturer’s Instructions

- HPWHs should be installed per the manufacturer’s guidelines to ensure proper operation and safety (IRC Section P2801.3).

- Space and Ventilation

- Ensure the installation location has sufficient airflow to support heat pump operation. Most manufacturers recommend a minimum of 700-750 cubic feet of air volume around the unit.

- If installed in a small room or closet, the door should have a louvered panel of at least 2 feet by 3 feet to allow adequate air circulation.

- Ground Clearance and Mounting

- HPWHs should be mounted on a level platform at least 3 inches above grade, with 6 inches of clearance on all sides for maintenance access (IRC Section M1305.1.4.1).

- For garage installations, HPWHs must be elevated 18 inches above the floor to prevent fire hazards (IRC Section P2801.7).

- Drain Pan and Condensate Drainage

- A drain pan must be installed beneath the water heater if leakage could cause damage, per IRC Section P2801.6.

- The condensate line should be piped to an appropriate drain or equipped with a condensate pump if gravity drainage isn’t possible.

Plan Review Checklist for HPWHs

Code officials should ensure the following details are included in the construction documents during the plan review phase:

Design and Equipment Specifications

- System Design Criteria

- Include HPWH capacity, efficiency ratings, and power requirements (typically 240V, 30A single-phase).

- Location and Ventilation

- Specify the installation space and airflow requirements, ensuring compliance with manufacturer recommendations.

- Drainage and Condensate Management

- Detail the installation of the drain pan and condensate drain line, including whether a pump will be used.

- Piping Design

- Show heat trap locations on hot and cold water lines to prevent thermo-siphoning.

- Indicate pipe insulation, which must meet the R-3 insulation requirement for hot water pipes (IECC Section R403.4).

- Electrical Connections

- Provide wiring details, including grounding, circuit breaker sizing, and panelboard identification.

Field Inspection Guidelines

During field inspections, code officials should verify that the HPWH installation meets the approved construction documents and applicable code sections. Key inspection points include:

Mechanical Inspection

- Location and Ventilation

- Ensure the HPWH is located in a space that provides adequate airflow, with clearances as specified by the manufacturer.

- If installed in a small space, verify that ventilation openings or louvered doors are installed correctly.

- Drain Pan and Condensate Line

- Check that the drain pan is installed properly and the condensate line is routed to an appropriate drain or equipped with a pump if necessary.

- Piping and Insulation

- Confirm that hot and cold water lines are properly insulated to a minimum R-value of 3 and that heat traps are installed on inlet and outlet lines.

Electrical Inspection

- Power Supply

- Verify that the power supply matches the unit’s requirements (typically 240V, 30A).

- Circuit Protection

- Ensure the proper circuit breaker or fuse is installed, and that the HPWH is identified on the panelboard.

- Grounding

- Confirm that the unit is properly grounded according to NEC and IRC requirements.

Additional Considerations for HPWH Installations

Cold Climate Installations

- In colder climates, HPWHs installed in unconditioned spaces such as garages may experience reduced efficiency. Most models include a hybrid mode that switches to electric-resistance heating when temperatures drop below a certain threshold, ensuring reliable hot water supply.

Noise and Location

- HPWHs produce noise in the range of 45-60 decibels during operation. Consider installing the unit in locations where noise will not disturb occupants, such as basements, laundry rooms, or garages.

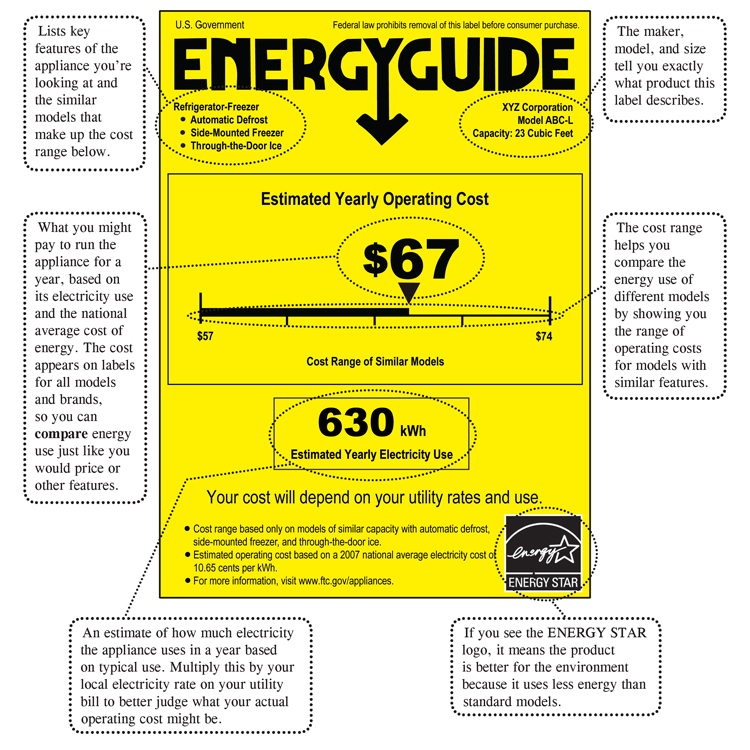

Energy Efficiency Benefits

- HPWHs are significantly more efficient than traditional electric water heaters, with some models achieving an Energy Factor (EF) of 2.0-3.0, meaning they can be two to three times more efficient than standard units. Installing HPWHs can help builders meet energy-efficiency targets set by the IECC.

Conclusion

Heat pump water heaters offer an energy-efficient solution for residential hot water needs, but proper installation is crucial to ensure performance, safety, and code compliance. By following the guidelines outlined in the 2015 and 2018 IRC/IECC, builders, contractors, and code officials can streamline the plan review and inspection process, resulting in fewer delays and greater compliance.

For immediate service or consultation, you may contact us at Allied Emergency Services, INC.

Contact Information:

- Phone: 1-800-792-0212

- Email: Info@AlliedEmergencyServices.com

- Location: Serving Illinois, Wisconsin, and Indiana with a focus on the greater Chicago area.

Disclaimer: This article is intended for informational purposes only. For professional advice, consult experts in the field.