Ensuring Code Compliance for Continuous Insulation and Cladding Attachments: Comprehensive Guide

As energy efficiency standards rise, the use of continuous insulation (c.i.) in wall assemblies has become essential. However, the installation of various cladding materials over thicker foam sheathing presents challenges. Without proper guidance, code officials, builders, and designers risk non-compliance due to conflicting manufacturer guidelines and code requirements. This article outlines key considerations and inspection protocols for ensuring compliance with the 2015 International Energy Conservation Code (IECC) and International Residential Code (IRC) for continuous insulation and cladding attachments.

Continuous Insulation and the Need for Updated Code Guidance

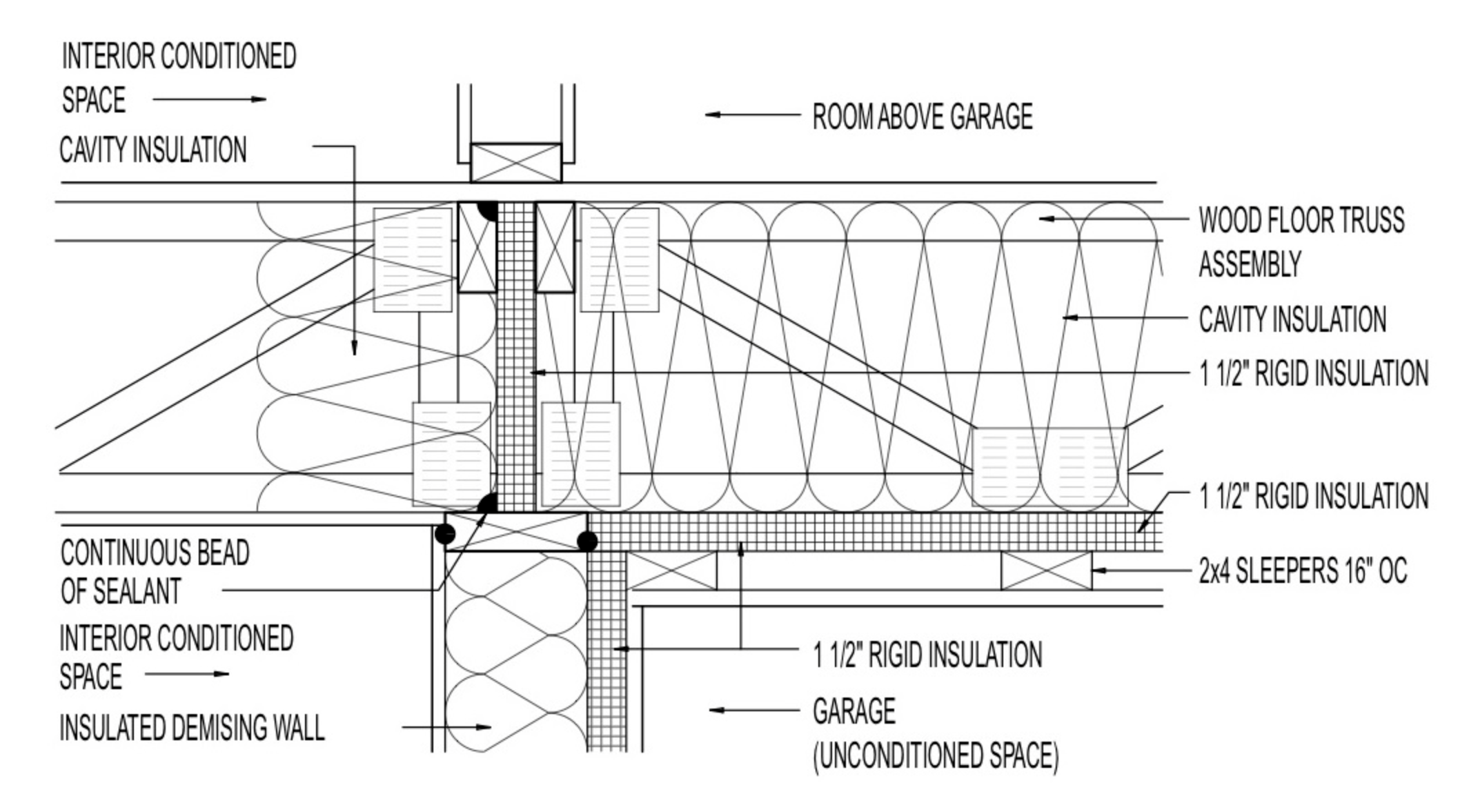

Continuous insulation improves thermal performance but requires special consideration for cladding attachment, particularly when the insulation exceeds 1.5 inches. Some building materials and manufacturers’ guidelines support only limited thicknesses, complicating installation. Here’s an overview of the main considerations:

- Appropriate Fasteners: Ensuring fasteners can support both the weight of the cladding and withstand wind and seismic loads.

- Non-standard Fasteners: Specifying alternative fasteners for insulation thicknesses beyond 1.5 inches.

- Manufacturer Limitations: Recognizing restrictions in manufacturer warranties for insulation exceeding certain thicknesses.

- Additional Support: Installing additional framing or detailing, especially for heavy claddings like stucco or masonry veneer, which require more rigid support.

For those working in jurisdictions without the 2015 IRC, referencing this guidance can help achieve compliance through the allowance for alternative materials and methods under Section R104.11/IRC and Section R102.1/IECC.

Key Code Sections for Continuous Insulation and Cladding Attachments

For streamlined installation and inspections, the following sections from the 2015 IECC/IRC outline essential requirements:

- Construction Documentation

- Sections R103.2/N1101.5: Construction documents should specify insulation R-values, moisture management strategies, and fastener details for cladding attachments. Plans should clearly outline insulation materials, R-values, and vapor retarders as required.

- Insulation and R-values

- Climate Zone-specific R-values are provided for both wood and steel framing, ensuring that wall assemblies meet minimum energy code requirements.

- Air Barrier Requirements

- The IECC emphasizes a continuous air barrier across the building envelope to limit air leakage. Section R402.4/N1102.4 requires sealing all joints, seams, and penetrations for air and moisture control.

- Attachment Requirements for Cladding and Furring

- Direct Cladding Attachment: For installations directly over foam sheathing, confirm that the construction documents meet Table R703.15.1 (wood framing) and Table R703.16.1 (steel framing) standards. Attachments must align with code-prescribed fastener types and spacings based on framing type, furring intervals, and cladding weight.

- Furred Cladding Attachment: For applications using furring strips, follow Table R703.15.2 (wood framing) and Table R703.16.2 (cold-formed steel framing). Ensure furring strips are spaced ≤ 24″ o.c. and meet the necessary specifications for both horizontal and vertical orientations.

2015 IECC Prescriptive Above-Grade Wall Insulation R-values

| Climate Zone | Wood Frame Wall | Steel Frame Wall (16″ o.c.) |

|---|---|---|

| 1, 2 | R-13 | R-13+5 or other equivalent |

| 3 | R-20 or R-13+5 | R-0+9.3 or equivalent |

| 4, 5 | R-20 or R-13+5 | Wood frame equivalent, varies |

| 6, 7, 8 | R-20+5 or R-13+10 | Wood frame equivalent, varies |

Plan Review Checklist

For code officials and builders, plan review is essential to verify that proposed designs comply with insulation and cladding attachment requirements:

- Insulation Materials and R-values

- Verify that specified R-values meet or exceed minimum code requirements for the project’s climate zone.

- Cladding Fasteners

- Check for adequate specifications of fastener type, diameter, and length to support the cladding over continuous insulation. This includes reviewing approved manufacturer instructions, particularly for installations over insulation thicker than 1.5 inches.

- Moisture and Vapor Management

- Ensure construction documents specify appropriate vapor retarders, weather barriers, and flashing details to mitigate moisture intrusion.

- Air Barrier Compliance

- Confirm the inclusion of a continuous air barrier for each wall assembly, including all required sealing measures for penetrations and seams.

- Wind and Seismic Load Calculations

- Confirm the design addresses local wind and seismic requirements, particularly for heavy cladding materials like masonry veneer.

Field Inspection Protocols for Continuous Insulation and Cladding

Field inspections play a crucial role in verifying code compliance for continuous insulation and cladding attachments. Inspections should focus on verifying materials and installation align with approved plans and code requirements.

Inspection Checklist:

- Insulation Installation

- Verify that insulation fills all cavities without gaps or compression, and confirm the R-value on the insulation matches approved specifications.

- Continuous Insulation (c.i.)

- Check that continuous insulation is installed per manufacturer guidelines, with the R-value mark visible for verification.

- Cladding and Furring Attachment

- Ensure that fasteners for cladding and furring meet installation requirements in the 2015 IRC Tables (R703.15.1, R703.16.1, R703.15.2, R703.16.2) for the specific cladding weight and insulation thickness.

- Air Barrier and Vapor Retarders

- Confirm that all seams, gaps, and penetrations in the insulation are sealed to create an effective air barrier. Vapor retarders should be installed on the warm side of the insulation in colder climates, meeting local code specifications.

- Inspection of Joints, Seams, and Penetrations

- Check that all joints and penetrations are properly sealed as per Section R402.4/N1102.4 to prevent air and moisture leaks.

- Weather-Resistant Barrier

- Inspect that moisture barriers, drainage, and flashing are installed in line with the code to prevent moisture intrusion and damage.

Conclusion

Proper installation of continuous insulation and cladding attachments in compliance with the IECC and IRC enhances energy efficiency, durability, and moisture control. By following these guidelines, builders, designers, and code officials can achieve a compliant, high-performance wall assembly that adheres to both energy efficiency and safety standards.

For further information or immediate consultation, please contact Allied Emergency Services, INC.

Contact Information:

- Phone: 1-800-792-0212

- Email: Info@AlliedEmergencyServices.com

- Location: Serving Illinois, Wisconsin, and Indiana with a focus on the greater Chicago area.

Disclaimer: This article is for informational purposes only. For professional advice, consult experts in the field.